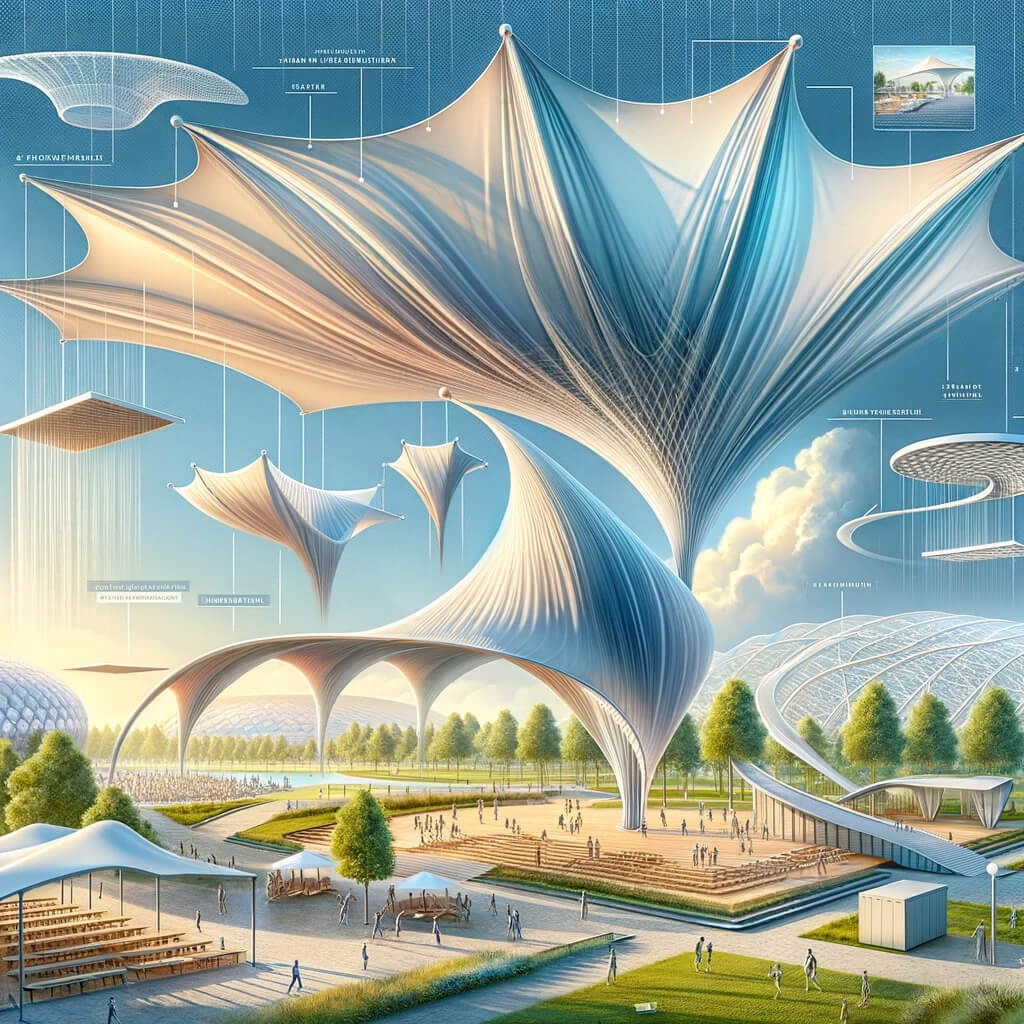

Discover the world of Tensile Structures, a remarkable architectural innovation transforming spaces into visually striking and functional environments.

Through tension rather than traditional construction methods, these lightweight, flexible designs offer an unparalleled blend of aesthetic appeal and practical efficiency.

Dive into our blog post to explore how tensile structures leverage cutting-edge materials and technology to create iconic landmarks, efficient sports arenas, and much more, reshaping our architectural landscape.

Table of Contents

What are Tensile Structures?

Tensile structures are architectural forms that carry loads primarily through tension rather than compression or bending. They are characterized by the tensioned fabric or flexible membrane materials they use, which are stretched between anchor points to create various shapes and surfaces. These materials can include but are not limited to, textiles, films, and thin metal sheets.

The key components of tensile structures include:

- Membrane Material: This is the primary component, which is tensioned to create the structure. The materials used are often lightweight, such as PVC-coated polyester, PTFE-coated fiberglass, ETFE foil, or other high-strength fabrics. These materials are chosen for their durability, translucency (in some cases), and weather resistance.

- Support Structure: This can be made of steel, aluminum, or composite materials, providing the points of attachment for the membrane and helping to shape it into the desired form.

- Anchoring System: Tensile structures require secure anchoring to resist the loads they carry and maintain tension in the membrane. Anchors can be connected to the ground, to buildings, or to specially designed foundation structures.

- Cables and Fittings: These are essential for applying tension to the membrane and can be adjusted to change the shape of the structure or to maintain tension over time.

Tensile structures are used in various applications due to their aesthetic appeal and functional benefits. They can cover large spans without internal supports, allowing for open and flexible use of space beneath. Their applications include sports arenas, exhibition halls, transport terminals, shade structures in public spaces, and even smaller installations like canopies over outdoor seating areas.

The benefits of tensile structures include:

- Lightweight Construction: They require less material than traditional structures, leading to lower costs and easier transportation and installation.

- Aesthetic Flexibility: They can be molded into various unique and attractive shapes, offering architects and designers creative freedom.

- Translucency: Certain membrane materials allow for natural daylighting, reducing the need for artificial lighting.

- Durability and Low Maintenance: The materials used are resistant to weather conditions and require minimal maintenance.

However, the design and construction of tensile structures require specialized knowledge and skills, including understanding the behavior of non-linear materials and the dynamics of tensioned systems.

3 sports arenas designed with Rhino Grasshopper

Rhino Grasshopper is a visual programming tool that is part of Rhinoceros 3D, a software used for computer-aided design (CAD), computer-aided manufacturing (CAM), 3D printing, and reverse engineering in industries such as architecture, industrial design, and multimedia.

Grasshopper allows designers to build forms and structures through a graphical algorithm editor, which can be particularly useful in the design of complex geometries and structures found in modern sports arenas. Below are three sports arenas that have utilized Rhino Grasshopper in their design process:

- Beijing National Stadium (Bird’s Nest): While the primary design software used for the Beijing National Stadium, also known as the Bird’s Nest, was not publicly specified as Rhino Grasshopper, the complexity and uniqueness of its design are indicative of the type of projects where Grasshopper would excel. The Bird’s Nest’s intricate steel structure, designed for the 2008 Olympic Games, exemplifies how advanced 3D modeling tools can contribute to innovative architectural designs.

- Allianz Arena in Munich, Germany: The Allianz Arena is renowned for its exterior of inflated ETFE plastic panels that can be illuminated in a full spectrum of colors. This kind of innovative facade design could benefit from the parametric and algorithmic design capabilities of Rhino Grasshopper, allowing for the exploration of various geometrical configurations and optimization of material usage.

- Mercedes-Benz Stadium in Atlanta, Georgia: Known for its retractable roof that resembles a camera aperture, the Mercedes-Benz Stadium is another example where Grasshopper could have been utilized to manage the geometric complexity and mechanical functionality of the roof structure. The design required a high degree of precision to ensure smooth operation and integration with the stadium’s overall architecture, which Grasshopper is well-equipped to handle through its algorithmic logic and parametric design capabilities.

While the specific use of Rhino Grasshopper in the design of these arenas might not be explicitly documented in public resources, the complex geometries and innovative structures of these projects are consistent with the types of challenges that Rhino Grasshopper is adept at addressing.

In the field of architectural design, especially in projects like sports arenas where both aesthetics and functionality are critical, Rhino Grasshopper is a valuable tool for exploring new forms and optimizing structures.

Fabric tensile structures

Fabric tensile structures are architectural forms that rely on tension rather than compression or bending to carry loads. These structures are characterized by the tensioned fabric or membrane surfaces stretched over a framework to create roofs, canopies, or even entire buildings.

The fabric often used is lightweight, such as PVC-coated polyester, PTFE-coated fiberglass, or ETFE foil, which allows for the creation of innovative, fluid shapes that are difficult to achieve with traditional materials like steel and concrete alone.

Advantages of Fabric Tensile Structures

- Lightweight: The materials used in fabric tensile structures are significantly lighter than traditional building materials, which can lead to savings on foundation and support structure costs.

- Aesthetically Unique: The flexibility of the fabric allows for the creation of distinctive, eye-catching forms that can become iconic landmarks.

- Natural Lighting: Translucent fabrics can be used to create areas that are well-lit with natural daylight, enhancing the ambiance of the space beneath and reducing the need for artificial lighting.

- Durability and Maintenance: Modern fabrics used in these structures are designed to be weather-resistant and durable, requiring minimal maintenance while withstanding harsh environmental conditions.

- Speed of Construction: Given the lightweight nature and prefabrication of many components, fabric tensile structures can be erected much faster than traditional buildings.

Applications

Fabric tensile structures are versatile and can be used in various applications, including:

- Sports Arenas: They provide shelter while allowing natural light, creating an inviting atmosphere for spectators and athletes.

- Public Spaces: Airports, train stations, and bus terminals often utilize tensile structures to create large, open, and inviting spaces.

- Exhibition Spaces and Pavilions: Temporary or permanent exhibition spaces benefit from the quick construction and unique aesthetics of fabric tensile structures.

- Retail and Commercial Spaces: Businesses often use tensile structures for their distinctive appearance and to attract attention.

- Educational and Recreational Facilities: Schools, universities, and recreational centers use fabric tensile structures to cover outdoor areas, sports facilities, or gathering spaces.

Notable Examples

- Denver International Airport: The terminal’s roof is made from a white Teflon-coated fiberglass fabric, creating an iconic series of peaks that resemble the snow-capped Rocky Mountains.

- The Millennium Dome in London (now known as The O2): This structure features a large fabric roof supported by masts, creating one of the largest domed structures in the world.

- Munich Olympic Stadium: Constructed for the 1972 Olympics, the stadium features a sweeping tensile fabric roof that extends over the stands and the adjacent parkland, creating a visually stunning landmark.

Fabric tensile structures demonstrate how innovative materials and engineering can come together to create spaces that are both functional and artistically expressive.

The development of new materials and computational design tools continues to push the boundaries of what is possible with fabric architecture, making it a field ripe with potential for future exploration and innovation.

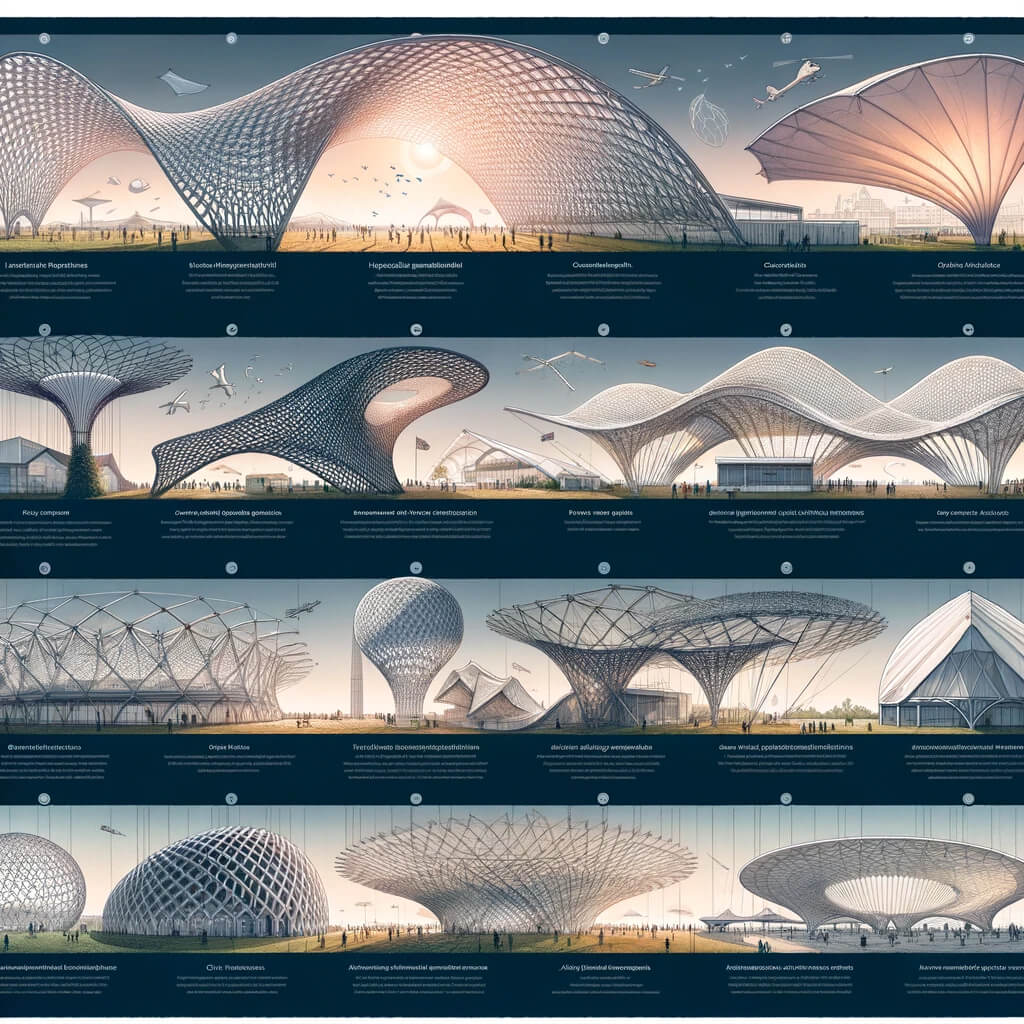

Types of tensile structures

Tensile structures, characterized by the use of tension rather than traditional compressive or bending construction methods, offer a variety of forms and applications that cater to diverse architectural and design needs.

These structures are typically made using flexible, durable materials such as coated fabrics or membranes that are tensioned to provide structural stability and an aesthetically pleasing appearance. The main types of tensile structures include:

1. Saddle Structures (Hypar)

- Description: Hypar (hyperbolic paraboloid) structures are shaped like a saddle, being simultaneously concave and convex. This geometry allows them to efficiently channel and distribute loads.

- Common Uses: Small pavilions, canopies over seating areas, or artistic features in landscapes.

2. Conical Tensile Structures

- Description: These structures are characterized by a conical shape formed by tensioning the membrane at several points around a perimeter to a central high point, creating a stable, self-supporting structure.

- Common Uses: Entrance canopies, small pavilions, or shade structures in public spaces, playgrounds, and outdoor seating areas.

3. Cable-Net Structures

- Description: Cable-net structures use a network of pre-stressed cables to support a flexible fabric membrane or glazing panels. The cables are typically arranged in a grid and anchored to a perimeter frame or boundary.

- Common Uses: Large-scale projects like sports stadiums, exhibition halls, or façade systems in architectural applications.

4. Tensile Fabric Facades

- Description: These are not full structures but rather tensile systems applied to the exterior of buildings as a secondary facade layer. They can provide shade, reduce heat gain, and enhance a building’s aesthetic appeal.

- Common Uses: Office buildings, commercial spaces, and any building seeking to improve energy efficiency and visual impact.

5. Air-Supported Structures

- Description: Air-supported structures are large, dome-like forms made from fabric and maintained by a slight internal overpressure. Entry and exit require airlocks to prevent the loss of internal pressure.

- Common Uses: Sports facilities, temporary event halls, and industrial storage.

6. Pneumatic Structures

- Description: Similar to air-supported structures but often incorporating more complex shapes or multiple chambers of air, pneumatic structures can achieve a wide range of forms and are relatively easy to erect and dismantle.

- Common Uses: Mobile pavilions, exhibition spaces, and temporary shelters.

7. Cable-Dome Structures

- Description: A cable-dome structure uses a double layer of tensioned cables (a net) linked by struts to form a dome-like shape. The tension in the cables supports the structure’s weight, making it suitable for covering large spans without internal supports.

- Common Uses: Sports arenas, large public gathering spaces, and exhibition halls.

8. Membrane Structures with Bending Elements

- Description: These combine tensile membranes with elements that undergo bending, such as arches or beams, to create forms that can span large areas while achieving unique aesthetic effects.

- Common Uses: Large canopies, walkway coverings, and integrated architectural elements.

Each type of tensile structure offers unique advantages in terms of aesthetics, functionality, and spatial qualities, making them suitable for a wide range of applications from small-scale installations to monumental architectural projects.

The choice of structure depends on the specific requirements of the project, including span, durability, cost, and visual impact.

Advantages and disadvantages of tensile structures

Tensile structures, known for their innovative and lightweight designs, offer several advantages and disadvantages that make them uniquely suited for certain types of architectural and structural applications. Here’s a comprehensive look at these pros and cons:

Advantages of Tensile Structures

- Aesthetic Appeal: Tensile structures can achieve unique and visually striking forms that are difficult to replicate with traditional construction methods. Their elegance and dynamism can turn functional structures into iconic landmarks.

- Lightweight Materials: The use of fabrics or membranes means these structures are much lighter than those built with conventional materials like steel, concrete, or wood. This can lead to savings in foundation and support structure costs.

- Large Span Capabilities: Tensile structures can cover large areas without the need for internal supports, providing clear, unobstructed spaces beneath. This makes them ideal for sports arenas, exhibition halls, and large public spaces.

- Translucency: Many membrane materials used in tensile structures allow natural light to penetrate, creating well-lit, inviting indoor environments and reducing the need for artificial lighting during the day.

- Quick to Install: As many components of tensile structures can be prefabricated, the on-site assembly and erection process is often faster than traditional construction, reducing overall project timelines.

- Energy Efficiency: The translucency of the fabric can contribute to energy savings by maximizing natural daylight. Additionally, the reflective properties of some membranes can help reduce heat gain, minimizing cooling costs in warmer climates.

- Durability and Weather Resistance: Modern tensile fabrics are engineered to be weather-resistant, durable, and capable of withstanding extreme conditions, including heavy winds and snow.

Disadvantages of Tensile Structures

- Limited Materials: The choice of materials for tensile structures is relatively limited compared to traditional construction, which can sometimes restrict design options or affect the project’s cost-effectiveness.

- Maintenance: While tensile materials are designed to be durable, they may require regular maintenance to ensure their longevity, including cleaning and protection from UV exposure, which can be challenging due to their shapes and heights.

- Design Complexity: The complex engineering and design process of tensile structures often requires specialized software and expertise, which can increase the design phase’s duration and cost.

- Permitting and Codes: In some jurisdictions, obtaining building permits for tensile structures can be more complicated due to their unconventional nature and the need for compliance with local building codes and standards.

- Thermal Insulation: Membrane materials used in tensile structures generally provide limited thermal insulation compared to traditional building materials, which can make them less energy-efficient in certain climates without additional insulation strategies.

- Acoustics: The hard surfaces of membrane materials can lead to poor acoustic performance, making sound management a challenge in environments where good acoustics are important, such as concert halls or theaters.

- Long-Term Performance: The long-term performance of tensile structures, particularly in harsh environments, can be uncertain. The lifespan of the fabric under UV radiation, pollution, and physical wear and tear is a consideration that needs careful planning and potentially higher lifecycle costs.

Despite these challenges, tensile structures remain a popular choice for projects requiring innovative design solutions, large clear spans, and a desire to make a visual statement.

The key to successfully implementing a tensile structure lies in addressing these disadvantages through careful planning, material selection, and incorporating design strategies that mitigate potential issues.

Kangaroo Tensile Structure

The term “Kangaroo Tensile Structure” likely refers to the use of “Kangaroo,” a physics engine for Grasshopper (the visual programming language add-on for Rhinoceros 3D), in the design and simulation of tensile structures.

Kangaroo enables designers and architects to explore physical behaviors and forces in their models, including tension, compression, bending, and inflation, among others.

This tool is instrumental in the creation of complex architectural forms that rely on the principles of tensile structures, such as fabric membranes, cable nets, and shell structures.

How Kangaroo is Used in Tensile Structure Design

- Form-Finding: Kangaroo allows for form-finding, which is a process to discover the optimal shapes of tensile structures under various loads and constraints. This is crucial for tensile architecture, where the shape of the structure directly influences its stability and performance.

- Simulation of Physical Behaviors: Through simulation, Kangaroo can predict how structures will behave under real-world physical forces, including gravity, wind, and snow loads. This helps in refining the design to ensure structural integrity and longevity.

- Material Optimization: By understanding the forces at play within a structure, designers can make informed decisions about material types and distribution, leading to efficient use of resources and potentially lowering the costs.

- Interactive Design and Adjustment: Kangaroo provides an interactive environment where designers can quickly adjust parameters and instantly see the effects on the structure’s behavior. This iterative process encourages experimentation and innovation in tensile structure design.

- Complex Geometry Handling: Tensile structures often feature complex geometries that are challenging to model with traditional CAD software. Kangaroo, integrated with Grasshopper, makes it easier to manipulate and optimize these complex shapes.

Applications in Tensile Structures

Kangaroo’s capabilities are particularly suited for the design and realization of tensile structures, including but not limited to:

- Architectural Canopies and Shade Structures: Designing lightweight, efficient canopies that respond to environmental conditions.

- Suspended and Cable-stayed Bridges: Simulating tension forces in cables to ensure structural stability.

- Membrane Structures: Finding the form of fabric structures that efficiently balance tension forces.

- Sculptural Installations: Creating art installations that rely on tension for their form and stability.

By leveraging Kangaroo in the design process, architects and engineers can push the boundaries of traditional architecture to create innovative, efficient, and visually striking tensile structures. This approach not only enhances the aesthetic appeal of the structures but also ensures they are practical, sustainable, and suited to their specific context and purpose.

Conclusion

In conclusion, tensile structures represent a fascinating intersection of art, engineering, and sustainability, offering solutions that are as aesthetically pleasing as they are functional.

By harnessing the potential of advanced materials and computational design tools, such as Rhino Grasshopper and Kangaroo, architects, and engineers are able to push the boundaries of traditional construction to create spaces that are not only innovative but also environmentally conscious and energy-efficient.

As we continue to explore and refine the capabilities of tensile structures, they stand as a testament to the ever-evolving landscape of architectural design, promising exciting possibilities for the future.